|

|

|

| Ask the Experts | |||||||

|

|||||||

|

April 24, 2025 - Updated December 3, 2014 - Originally Posted Cleanliness Standards for Electronic ComponentsI work as a supplier engineer in our automotive division and we are very concerned about cleanliness for electronic components. We have a very stringent humidity and temp test from one of our OEM's that causes dendrites almost every time we run the test. I have been looking for cleanliness standards for electronic components but the only thing I have been able to find is for PWB cleanliness. To date I have not been able to find any standards regarding cleanliness specifications for ionics for electronic components specifically. Are there for electronic component cleanliness in the industry currently or are there plans to review cleanliness requirements for components? D.D. |

|||||||

| Expert Panel Responses | |||||||

|

Component cleanliness is "sort of" covered within the JEDEC standards, but typically they will reference MIL-PRF-STDs for component cleanliness. Two JEDEC standards I can recommend you begin your search with are JEDEC STD 22-B102E, and JESD9B, specifically section 8.1 which uses the words "metallization" to cover any conductive condition, including under-etched metal, crystallization, dendrites,and so forth. Anyone can get the JEDEC standards by simply going to www.jedec.org and registering; it is free of charge. Also they are cheaper than sleeping pills, and more effective.

Advanced Engineer/Scientist General Dynamics Richard D. Stadem is an advanced engineer/scientist for General Dynamics and is also a consulting engineer for other companies. He has 38 years of engineering experience having worked for Honeywell, ADC, Pemstar (now Benchmark), Analog Technologies, and General Dynamics.

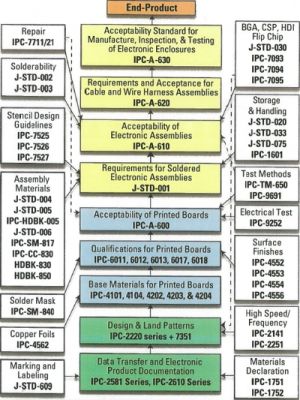

Try IPC/JEDEC J-STD-033,Handling, Packing, Shipping and Use of Moisture/Reflow Sensitive Surface Mount Devices,see image below, of IPC Standards,you should find what you are looking for under "Storage and Handling."

Process Engineering Manager - Electronics Altech UEC, South Africa Currently with Altech UEC and responsible for technology road map in PCBA electronic manufacturing and technical support for PCBA electronic manufacturing for Altech UEC and its JDM's. Over 7 years in SMT, Radial Insertion, Wave solder & Test Applications.

I have not seen any other document that provides specs for component cleanliness other than IPC but you are not the only one experiencing this phenomena. Dendrites will form when current & moisture are introduced to two adjacent conductors. Even distilled water can caused dendrites if the right conditions are met. You did not mention if these components are going to be conformal coated. You could avoid formation of dendrites if you provide a conformal coat to the components or area surrounding them.

Senior Manufacturing Engineer Northrop Grumman Edithel is a chemical engineer with 20 year experience in manufacturing & process development for electronic contract manufacturers in US as well as some major OEM's. Involved in SMT, Reflow, Wave and other assembly operations entailing conformal coating and robotics.

From a humidity standpoint, the dewing test is a difficult one. As a materials company who supplies solder paste to automotive applications where the no-clean residue is not cleaned off post-reflow, we have pastes that pass the BMW dewing test. From a temperature standpoint, we have seen instances of dendritic growth under flat-bottom components for dry heat testing (120 deg C for 21 days). The ionics and residue characteristics of the solder paste can be engineered to address this issue.

Technical Manager - Europe Indium Corp. Currently with Indium Corporation and responsible for technology programs and technical support for customers in Europe. Over 15 yrs experience in SMT, Power, Thermal & Semiconductor Applications. Masters Degree in Industrial Engg, State University of New York-Binghamton.

There are no present standards for how clean a component has to be to have long term reliability, either in IPC or IEC. There are some standards for how clean assemblies need to be, but those standards are presently being updated and the old standards are being obsoleted. Ion Chromatography is the tool of choice for determining component cleanliness.

Principal Materials and Process Engineer Collins Aerospace Doug Pauls has a bachelors in Chemistry & Physics, Carthage College, BSEE, Univ of Wisc Madison. He has 9 years working experience for US Navy - Materials Lab, Naval Avionics Center Indianapolis. 8 years Technical Director, Contamination Studies Laboratories. 11 years Rockwell Collins Advanced Operations Engineering.

Reader Comment

Currently there is one standard that is applied for electronic piece parts and it is the GEIA-STD-006 post solder dip to replace final finish.

Joe Russeau, Precision Analytical Laboratory, Inc.

It utilizes the Resistivity of Solvent Extract (aka ROSE) test, which is an improper application of that technique IMHO. There are no IPC derived requirements or methods for component cleanliness at this time. However, as I am the IPC chairman for the Ionic Conductivity Task Group I would encourage you and others to come to our meeting in the Fall at SMTAi to throw out some idea's. The IPC is the best source for standards for our industry, Electronics Assembly. In your case, a standard for cleanliness, the IPC/EIA J-STD-001, "Requirement for Solder Electrical and Electronic Assemblies" has your answer in section 8, "Cleaning Process Requirements." If you do not have a copy of this standard, please go to the IPC's site and buy one. This helps support the great people who produce these standards. How clean electronic components and assemblies must be is up to your customer and you should seek their input on what they require first. Some high impedance circuitry requires extreme cleanliness and others have no real concern. The IPC/EIA J-STD-001 section 8 outlines a "Cleanliness Designator" beginning with the letter "C-" and two digits that follow. This is a standard way for your customer to specify what to clean and to what extent they want you to test to prove cleanliness. As I read the standard, section 8 indicates that "Assemblies shall be free of dirt, lint, solder splash, dross, wire clippings, etc." and "Unless specified by the user..." (your customer) all assemblies shall meet the default cleanliness designator "C-22" which means, "Both sides of assembly shall be cleaned" and a "Test for ionic residues required." The complete details of the Cleanliness Designator and the testing methods are outlined in the standard, section 8. Your customer needs to specify a cleanliness designator for you to follow or you must use the default designator C-22, if you intend to meet the requirements of the IPC/EIA J-STD-001 standard.

Senior Project Engineer Electronic Controls Design Inc Paul been with Electronic Controls Design Inc. (ECD) in Milwaukie, Oregon for over 39 years as a Senior Project Engineer. He has seen and worked with the electronic manufacturing industry from many points of view, including: technician, engineer, manufacture, and customer. His focus has been the design and application of measurement tools used to improve manufacturing thermal processes and well as moisture sensitive component storage solutions.

|

|||||||

| Submit A Comment | |||||||

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address. |

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it. Insert Your Email Address |

|

|