|

|

|

| Ask the Experts | |||||||||||||

|

|||||||||||||

|

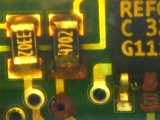

March 20, 2025 - Updated October 19, 2016 - Originally Posted What Is This Contamination?These images are from a failed position-sensor in our power plant. It is potted with some kind of epoxy-compound because of vibration-issues. We don't think the potting is done by the manufacturer, it is more likely done later in the assembly-line because it's done only for us.

What do you think? What are we seeing here? This sensor failed after only 2-3 years of operation among with several others. M.K. |

|||||||||||||

| Expert Panel Responses | |||||||||||||

|

Need to know the surface finish on the PWB.

President S T and S Testing and Analysis Gerald O'Brien is Chairman of ANSI J-STD 003, and Co Chairman of IPC 4-14 Surface Finish Plating Committee. He is a key member of ANSI J-STD 002 and 311 G Committees Expert in Surface finish, Solderability issues and Failure analysis in the PWA, PWB and component fields.

Looking at the images gives me several ideas as to what happened:

Senior Manufacturing Engineer Northrop Grumman Edithel is a chemical engineer with 20 year experience in manufacturing & process development for electronic contract manufacturers in US as well as some major OEM's. Involved in SMT, Reflow, Wave and other assembly operations entailing conformal coating and robotics.

There is almost definitely corrosion going on, so the question is what is the source? From what we can see, it is limited to certain terminals, so my working hypothesis would be assembly soils that were not removed and later created an ionic path between terminals where a voltage gradient exists. The ionic path and moisture permeating the potting compound then combined with the voltage difference to drive corrosion of the terminals. This theory plays well with your hypothesis that the potting is being done at a post-assembly step. If the potting is done at a different location/organization than the assembly, they may not understand what soils are present, e.g. flux residues, and may not be taking the proper steps to ensure reliability.

Process Engineer Astronautics Fritz's career in electronics manufacturing has included diverse engineering roles including PWB fabrication, thick film print & fire, SMT and wave/selective solder process engineering, and electronics materials development and marketing. Fritz's educational background is in mechanical engineering with an emphasis on materials science. Design of Experiments (DoE) techniques have been an area of independent study. Fritz has published over a dozen papers at various industry conferences.

From the picture, it is difficult to be sure. I would suggest there is a corrosive contaminant under the epoxy coating, likely left-over residue from a so called "no clean" flux. Before the Epoxy coating is applied, the assembly must be cleaned no matter what type of solder flux used. Such corrosion can also be caused by other contamination left behind by the assembly process, even finger prints.

Senior Project Engineer Electronic Controls Design Inc Paul been with Electronic Controls Design Inc. (ECD) in Milwaukie, Oregon for over 39 years as a Senior Project Engineer. He has seen and worked with the electronic manufacturing industry from many points of view, including: technician, engineer, manufacture, and customer. His focus has been the design and application of measurement tools used to improve manufacturing thermal processes and well as moisture sensitive component storage solutions.

The pictures are difficult to zoom into but it appears there is corrosion occurring. Is there a no clean flux on these circuit boards? If so that could be a potential source for corrosion, especially when the device is in operation. Potting material does not necessarily stop corrosion or electro migration from occurring. It likely slows the process enabling the device to operate over a longer period of time before failure.

Field Applications FCT Assembly Tony has worked in the electronics industry since 1994. He worked as a process engineer at a circuit board manufacturer for 5 years. Since 1999, Tony has worked for FCT Companies as a laboratory manager, facility manager, and most recently a field application engineer. He has extensive experience doing research and development, quality control, and technical service with products used to manufacture and assemble printed circuit boards. He holds B.S. and M.B.S. degrees in Chemistry.

The images from a failed position-sensor used in your power plant, appear to be potted or staked with some kind of epoxy-compound because of end application vibration-issues. You don't think the potting is done by the manufacturer, it is more likely done later in the assembly-line because it's done only for you. This sensor failed after only 2-3 years of operation. How long do known good assemblies last for comparison? Typically, when I encounter contamination of circuit card assemblies I recommend comparing a known good verses bad and extracting several samples for different locations to submit for FTIR, SEM/EDX, and IC analysis testing. The FTIR in my humble opinion will be the fastest and the cheapest for organics ( e.g., residual flux, adhesives , or coatings chemistry) that may result in subsequent contamination or corrosion failures. The SEM/EDX allows me to determine the inorganics involved ( e.g., Metals) that do not contain carbon. They have high melting points and particular high or low electrical conductivity properties. Inorganic substances are used in many applications and in various fields.. Often, they are used as coatings, catalysts, medicines, pigments and fuels. Finally, I would submit the known good verses bad circuit card assemblies for IC testing to identify Ionics per IPC-TM-650-2.3.28. IC testing will reveal anions and cations involved and specific levels critical to board assembly cleanliness. When certain levels are exceeded and exposed to moisture , bias, and temperatures subsequent contamination or corrosion failures result. After doing this analysis you will be able to determine if the failure is a result of supplier issues( e.g., Flux, adhesive, coating), Manufacturing(e.g., process problem) , Design ( e.g., pitch issues) , or end application ( e.g., harsh environment ).

Fellow Raytheon Mark has over 35 years of experience in electronics fabrication, quality, and reliability while working for Raytheon RMD, IEC Electronics, GE, Motorola, ORS, etc. He has most recently taken the role as a Fellow at Raytheon in Tucson, AZ; prior to that, he established IEC Electronics Analysis and Testing Laboratories (IATL), LLC in Albuquerque, NM, for electronics and material analysis testing in the military, medical, and industrial industries. His expertise includes PCB, PCBA, components, and analytical and electrical analysis techniques.

Very difficult to determine the cause from the pictures provided, however there appears to be a conformal coat or potting present on the board. From the bubbles between the leads on the IC it looks to be the original application. I am guessing you are seeing 1 of 2 items, either poor rework was performed prior to conformal coat during the manufacturing process or there is a net in board getting hot. I would need to look at this under a scope to really determine what is going on. I am leaning toward rework during the manufacturing process and flux was not removed prior to potting.

Director of Corporate Quality Assurance Delta Group Electronics Inc. Tod has been working in the Aerospace Electronics Industry for 25 years, beginning with 4+ years working for PCB fabricator ending as the Quality Manager and 20 years with Delta Group Electronics Inc. an AS9100 registered electronics contract manufacture. Currently position is Director of Corporate Quality Assurance.

Without further investigation, I can only guess this board suffered a short. Most likely from an insufficient cleaning process and possibly dendrite growth. It is very possible flux residue was left behind which may past initial testing but fail later in the field.

Manufacturing Applications Specialist Cirtronics Corp. Mr. Bush has over 30 years of experience in electronics contract manufacturing. Major areas of expertise include through-hole, SMT, wave, and selective soldering.

This looks like some form of corrosion. Most likely this was cause by flux residues beneath the coating. Any applied coating to prevent environmental conditions from affecting the product are not impervious to the absorption of moisture. Hence, if the unit has been in the field for two years, then the operating environment may be the source of the mechanism for the corrosion on the product. My recommendations would be to have the material analyzed to determine the exact material composition, which can then be evaluated as to its source and control of such.

Vice President, Technical Director EPTAC Corporation At EPTAC Corporation, Mr. Lambert oversees content of course offerings, IPC Certification programs and provides customers with expert consultation in electronics manufacturing, including RoHS/WEEE and lead free issues. Leo is also the IPC General Chairman for the Assembly/Joining Process Committee.

Looks likely you have some corrosive residue left in the via and leaching out, causing the corrosion and subsequent failure. Is this on the power part of the PCB? I would suspect something pretty active (Hydrochloric/Hydrobromic Acid) especially if the finish of the PCB is HASL and it won't matter if its coated or not it will still corrode and sometimes faster with the coating on.

Technical Sales Manager BLT Circuit Services Ltd Greg York has over thirty two years of service in Electronics industry. York has installed over 600 Lead Free Lines in Europe with Solder and flux systems as well as Technical Support on SMT lines and trouble shooting.

In looking at the photos below, I would suspect that the contamination is actually corrosion. We see this quite frequently.

General Manager Trace Laboratories Renee has been with Trace and an IPC member for 16 years. She has managed all military and commercial PB qualification and conformance testing and training, as well as product qualification and testing in the areas of solder pastes, fluxes, solder masks, and conformal coat. She is the chairman of the IPC Testing and the IPC-J-STD-004 Flux Specification Committees and the Vice Chairman of the Assembly and Joining Committee. She has published more than a dozen papers and presented at numerous electronics conferences.

With not a lot of data here are few things that I can think about - this can be some sort of oxidation caused by contamination in the assembly process:

Engineering and Operations Management Independent Consultant Georgian Simion is an independent consultant with 20+ years in electronics manufacturing engineering and operations.

Contact me at georgiansimion@yahoo.com. Reader Comment

Agreed, from the photos it looks like white flux residue on the boards. White residue is usually (but not always) salts, which are the “activators” in the fluxes. When these salts meet heat or other chemicals, white residue can result. This residue can corrode delicate circuits. There are many possible sources for the residue. The boards, the cleaning fluids and fluxes used, the cleaning processes, the way the fluxes and solder paste are stored, and even the weather. It is very hard to determine precisely what might be causing the problem.

Sheri Pear, Micro Care

There are three likely places to look: the contamination, the cleaning fluid, and then the process. 1. Look for a change in what you’re trying to clean. For example, have you just switched to lead-free? Or, did a spool of RMA solder get slipped into a “no clean” process? These material changes can cause unexpected residue and cleaning problems. 2. Check for a mismatch between the cleaner and the contamination. If the residue is an even, smooth layer of white film across a large area this usually indicates you have the wrong cleaner. 3. Review the cleaning process. Look for streaks or spots of white residues. These are the indicators of improper cleaning technique. I don't think I see corrosion here. Corrosion is not selective, and does not discriminate on where it wants to appear. Especially on an ENIG board, which this appears to be, but like the others said, the picture is not clear. You said the board was potted, but this looks like the potting was removed to troubleshoot the failure cause, but some was left behind. The other thing I noticed is that the affected areas appear to be in series with each other, such as the 4702 resistor in series with the via, and the via connected to the two leads on the IC, and so forth. I have never seen corrosion so thick that it is bulging out of the vias either. What I think happened here was that there was some type of short circuit or overheated circuit, and that particular circuit got really hot, causing the potting to burn. When the potting was removed, it appears to have come off easily except at certain points where it got burnt on, so to speak. But without a lot more information and some better pictures we could all speculate all day and not come to any firm conclusion.

Advanced Engineer/Scientist General Dynamics Richard D. Stadem is an advanced engineer/scientist for General Dynamics and is also a consulting engineer for other companies. He has 38 years of engineering experience having worked for Honeywell, ADC, Pemstar (now Benchmark), Analog Technologies, and General Dynamics.

|

|||||||||||||

| Submit A Comment | |||||||||||||

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address. |

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it. Insert Your Email Address |

|

|