|

|

|

| Ask the Experts | |||||||

|

|||||||

|

May 16, 2025 - Updated February 23, 2022 - Originally Posted Flux Residue During Pin-in-PasteOur application is for pin-in-paste reflow using tin/lead no-clean, solder paste. Is it standard practice to increase the bottom side temperature to ensure the flux residue has been sufficiently activated and the flux residue is harder vs. softer and slightly gooey? M.W. |

|||||||

| Expert Panel Responses | |||||||

|

I would not increase reflow temperature to attempt to harden residues. Extent of hardening of residues is highly dependent on the flux chemistry, and in addition is dependent on time after reflow; the residues react with oxygen and harden over time. Pin-in-paste applications can be challenging because of the sheer amounts of residues present, which increases the time required for any reaction with atmospheric oxygen. The reflow process should be controlled to produce the needed peak temperature and time over liquidus. Excess time/temperature can be detrimental, for example can enhance formation of a thicker layer of intermetallic compounds, which can impact reliability.

Process Engineer Astronautics Fritz's career in electronics manufacturing has included diverse engineering roles including PWB fabrication, thick film print & fire, SMT and wave/selective solder process engineering, and electronics materials development and marketing. Fritz's educational background is in mechanical engineering with an emphasis on materials science. Design of Experiments (DoE) techniques have been an area of independent study. Fritz has published over a dozen papers at various industry conferences.

The choice of whether to have hard or soft residues will be influenced if there is a need to electrically test these features that you are using PIP for. Bull nose test probes will typically not penetrate a hard residue and soft sticky residues will gum up the test pins, both ultimately giving the same open type defect. In the past we had to change pastes to allow for probing through the residue with gumming up the probe tips.

President S T and S Testing and Analysis Gerald O'Brien is Chairman of ANSI J-STD 003, and Co Chairman of IPC 4-14 Surface Finish Plating Committee. He is a key member of ANSI J-STD 002 and 311 G Committees Expert in Surface finish, Solderability issues and Failure analysis in the PWA, PWB and component fields.

To my knowledge there is no standard practice for pin in paste reflow. It depends upon the board design, components, and the volume of solder paste applied, which makes every application a bit unique. The amount of heat required for no clean flux residues to be "safe" to leave on the PCBA depends upon the solder paste used. I recommend measuring the reflow profile with thermocouples on the top and bottom surfaces of the PCBA near the through hole solder joints in question. Then set the oven to give a profile which meets the solder paste manufacturer’s specifications for both top and bottom sides. That would be the best way to handle this situation.

Field Applications FCT Assembly Tony has worked in the electronics industry since 1994. He worked as a process engineer at a circuit board manufacturer for 5 years. Since 1999, Tony has worked for FCT Companies as a laboratory manager, facility manager, and most recently a field application engineer. He has extensive experience doing research and development, quality control, and technical service with products used to manufacture and assemble printed circuit boards. He holds B.S. and M.B.S. degrees in Chemistry.

I do pin and paste regularly. I do not necessarily increase the bottom side reflow temperature. That is not to say I wouldn't if the parameters warranted — i.e. thickness, ground plane, thermal mass, etc. Using a thermal profiler and my paste parameters, I place thermocouples on both sides of the board in those locations to ensure reflow temps on the surface and in the barrel. I use a traditional soak profile (as opposed to a ramp) allowing the flux to remove any oxides in the barrel. In all cases so far, both the top and bottom side oven temperatures are the same.

SMT Engineer ACDi Mr. Harman is an SMT Engineer at ACDi and worked at Oven Industries as a Manufacturing Engineer. H's worked at Philips manufacturing ultrasound probes/circuitry. He holds three patents, one for an ultrasound probe design, and two for innovative rat/mouse zapper circuits. He attended Pennsylvania State University for Electrical Engineering.

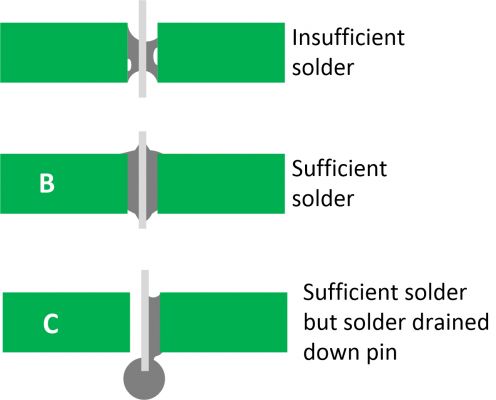

Interesting question and difficult to answer without additional detail, but I will try to answer in a generic manner. The biggest issues with pin-in-paste soldering are: 1) Having enough solder paste (especially in thick boards) 2) Keeping solder where it belongs 3) Ensuring proper thermal profile Manufacturer's recommendation for solder paste profile must be adhered to (minor tweaks to suit the board technology/application). If the solder paste volume is incorrect, then the solder joint may be substandard (insufficiently wetted as in graphic "A", below). One problem with having the bottom side hotter than the top side is that the solder may drain down the pin and in extreme cases my form a ball at the end of the pin (see graphic "C").

Besides not meeting standards, "C" may interfere with test fixtures or clearances for mechanical assembly. Follow solder paste manufacturer’s thermal profile by careful control of board temperature, top and bottom. A properly instrumented thermal profile board is absolutely required to verify proper profile. This is important, not only for good solder wetting, but also for the quality of the solder paste residue. Ensure that solder paste volume is sufficient for proper solder joint result.

President Colab Engineering A thirty year veteran of electronics assembly with major OEMs including Digital Equipment Corp., Compaq and Hewlett-Packard. President of Colab Engineering, LLC; a consulting agency specializing in electronics manufacturing, root-cause analysis and manufacturing improvement. Holder of six U.S. process patents. Authored several sections and chapters on circuit assembly for industry handbooks. Wrote a treatise on laser soldering for Laser Institute of America's LIA Handbook of Laser Materials Processing. Diverse background includes significant stints and contributions in electrochemistry, photovoltaics, silicon crystal growth and laser processing prior to entering the world of PCAs. Member of SMTA. Member of the Technical Journal Committee of the Surface Mount Technology Association.

|

|||||||

| Submit A Comment | |||||||

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address. |

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it. Insert Your Email Address |

|

|