|

|

|

|

|

|

|

|

|

|

|

|

| Ask the Experts | |||||||

|

|||||||

|

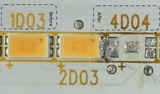

September 19, 2023 - Updated July 30, 2013 - Originally Posted Legend Marking Discoloration

Can you recommend a process to prevent this from happening? G.M. |

|||||||

| Expert Panel Responses | |||||||

|

Ensure overheating is not taking place. Measure the temperature of the areas of interest with thermocouples. If OK, try reworking in a nitrogen (low oxygen) environment, this approach has minimized the darkening of light colored boards (G10) for both site Rework and mass Reflow.

Regional Sales Manager Finetech Al Cabral is Regional Sales Manager for Finetech and Martin rework products. His expertise includes through-hole, surface mount and semiconductor packaging with an emphasis on soldering and heat transfer. Al has been a significant contributor to the development and optimization of reflow and rework processes and systems, particularly lead-free transitions and microelectronic applications.

Engineering and Operations Management Independent Consultant Georgian Simion is an independent consultant with 20+ years in electronics manufacturing engineering and operations.

Contact me at georgiansimion@yahoo.com. The darkening is of course caused by thermal decomposition of the ink. This type of degradation is typically accelerated above a threshold temperature that dependent on the ink chemistry, and possibly on the chemical exposure history of the ink. If the rework is being done with a hot air system, consider conducting an experiment. Expose some legend ink to the air flow using the normal rework temperature set point. Control the time and distance, and note how quickly the discoloration occurs. Now start reducing the temperature in steps of say, 20C, and for each step record the same information. You will find that there is a temperature below which it takes a very long time to discolor the ink; you already know that it's not discolored by exposure to your reflow profile, so that provides one data point. The question is, will the maximum workable set point that avoids degradation still provide adequate heat to rework the components in a reasonable time? If not, you may need to investigate whether you can change the ink to a more robust product. Another alternative might be to pre-heat the assemblies to be reworked, which will lower the set point required during rework.

Process Engineer Astronautics Fritz's career in electronics manufacturing has included diverse engineering roles including PWB fabrication, thick film print & fire, SMT and wave/selective solder process engineering, and electronics materials development and marketing. Fritz's educational background is in mechanical engineering with an emphasis on materials science. Design of Experiments (DoE) techniques have been an area of independent study. Fritz has published over a dozen papers at various industry conferences.

I cannot think a process to prevent this from happening, other than shielding the total area around the component where the markings exists. However discolored markings are acceptable, so discoloration should not be a problem.

Vice President, Technical Director EPTAC Corporation At EPTAC Corporation, Mr. Lambert oversees content of course offerings, IPC Certification programs and provides customers with expert consultation in electronics manufacturing, including RoHS/WEEE and lead free issues. Leo is also the IPC General Chairman for the Assembly/Joining Process Committee.

I will make the assumption that you are using hot air to perform the rework. If this is true you will need to make sure that the air temperature blowing on the rework site stays below 300C. Using lower air temperatures will extend the rework cycle a bit, but should give you better results with both the solder joints and cosmetics. If you want to get rid of the discoloration without changing the thermal process, then apply Kapton tapeover the markings prior to rework.

President Process Sciences, Inc. Stephen Schoppe is President of Process Sciences, Inc., and has 19 years experience providing SMT services to electronics manufacturers. Stephen provides consulting to several Fortune 500 clients on solder and SMT processes, and is a frequent guest speaker at SMT industry events.

The symbolization epoxy is usually initially anatase-based, which provides the brilliant definition. However, this phase changes to rutile in the presence of heat and then the crystals become almost like xenotine. Both the rutile stage and xenotine have more of a pinkish tan or almost beige color. So when heated, the anatase properties become rutile and thus the color change. Also, the anatase is optically negative and rutile is positive. This tends to accentuate the color change. This is very common, especially when rosin-based fluxes are in contact with the symbolization. It is a chemical reaction brought on by heat. I have seen it happen many times, but it was not really a concern as the symbolization was still very legible. It is still inert. It is a cosmetic issue only.

Advanced Engineer/Scientist General Dynamics Richard D. Stadem is an advanced engineer/scientist for General Dynamics and is also a consulting engineer for other companies. He has 38 years of engineering experience having worked for Honeywell, ADC, Pemstar (now Benchmark), Analog Technologies, and General Dynamics.

Reader Comment

Apply kapton tape or adhesive backed heat shield blanket. (235-4010 Heat Shield Blanket, 5" x 7" ) CircuitMedic sells them and are not expensive.

Sundaram, EIT LLC

|

|||||||

| Submit A Comment | |||||||

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address. |

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it. Insert Your Email Address |

|

|

|

|

|

|

|

|