| Sponsor |

|

Need a Profiler Plan B?

Tired of having to share a thermal profiler across different soldering operations? Add the affordable V-M.O.L.E. 2 four-channel profiler to the mix for time-saving efficiency.

ECD

|

|

| Sponsor |

|

Fast PCBs, Fully Assembled

Need it fast? Summit delivers quick-turn PCB fabrication and assembly on compressed timelines—no shortcuts, just speed and precision from one source.

Summit Interconnect

|

|

| Ask the Experts |

|

|

May 2, 2012 - Updated

April 24, 2012 - Originally Posted

Solder Mask Mis-registration Issue

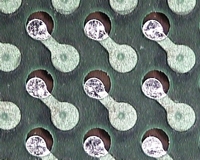

I have a situation where solder mask wasmis-registered and is covering a portion of the pads for amicro-bga.

What percent reduction in pad areais acceptable while maintaining a reliable solder joint for commercialapplications?

R.L.

|

| Expert Panel Responses |

Let's start with the industry specifications; IPC-6012 statesthat no encroachment of mask on non-soldermask-defined BGA lands is allowable,except of course at the conductor attachment point. The reason behind this isthat the BGA solder joint takes up all the thermal and mechanical stresses betweenthe component and board, unlike leaded parts where the leads absorb some of therelative movement. For this reason, things that reduce the solder joint area,or create "stress risers" (sharp internal corners) are to be avoided.

The reliability impact for your specific situation depends on alot of factors, and a detailed analysis would need to be done to determine thelevel of risk. The bottom line, though, is that if the PWBs were purchased toIPC-6012, they do not conform.

Suppliers can nearlyalways hold soldermask registration within a true position of 0.003". Supplierswith more modern imaging technology may be able to hold 0.002". You don't saywhat pitch your part is, but it looks to me like the soldermask registrationmay be close to accepted registration tolerances. You will need to look at thedesign vs. the supplier's process capability to determine whether changes tothe design may make it more producible.

Fritz Byle

Process Engineer

Astronautics

Fritz's career in electronics manufacturing has included diverse engineering roles including PWB fabrication, thick film print & fire, SMT and wave/selective solder process engineering, and electronics materials development and marketing. Fritz's educational background is in mechanical engineering with an emphasis on materials science. Design of Experiments (DoE) techniques have been an area of independent study. Fritz has published over a dozen papers at various industry conferences.

I would say there should be no tolerance to resistbleed onto BGA pads. Mostly because there are Plasticizers that are very clearthat can creep out from the main body of the resist and reduce actual wettingto the pad. But obviously the BGA ball will still melt and may look perfectlyfine but be a future issue electrically and mechanically.

Greg York

Technical Sales Manager

BLT Circuit Services Ltd

Greg York has over thirty two years of service in Electronics industry. York has installed over 600 Lead Free Lines in Europe with Solder and flux systems as well as Technical Support on SMT lines and trouble shooting.

|

|

Submit A Comment

|

Comments are reviewed prior to posting. You must include your full name to have your comments posted. We will not post your email address.

|

Free Newsletter Subscription

Circuitnet is built for professionals who bear the responsibility of looking ahead, imagining the future, and preparing for it.

Insert Your Email Address

|

|